Being alert to the world’s agenda on climate change, oil refineries in Thailand are striving to employ advanced and proven technologies to reduce greenhouse gas emission and energy consumption derived from the operations. The undertaking is part of their efforts to lend meaningful contributions to address the global warming problems.

At the recent webinar entitled “Sustainable Refinery Trend and Technology” organized by the Petroleum Institute of Thailand (PTIT), representatives from Dow Thailand, leading materials science company, spoke to the audience about the proven, reliable and affordable technology invented to cope with the refinery efficiency and environmental issues while a speaker from IRPC Public Company Limited shared to participants about its experience in applying that solution to achieve energy saving and environmental protection.

Vichan Tangkengsirisin, Asia Pacific Commercial Director, Dow Industrial Solutions, said in the webinar that world population are awakening to climate change crisis. Many countries are attempting to succeed carbon neutral target and aiming for net zero emission of GHG in 2050, in order to achieve the goal of the Paris Agreement that limit global temperature increase to well below 2 degrees Celsius, while pursuing efforts to limit the increase to 1.5 degrees. Considering that GHGs are emitted from combustion of fossil fuels such as oil and coal, global trend is now lowering reliance on fossil fuels and moving to clean energy. However, the transition is still going on and relying on fossil fuels which can’t be cut off immediately. The answer to this situation is finding out “how to use energy efficiently and reduce GHG emission at the same time”

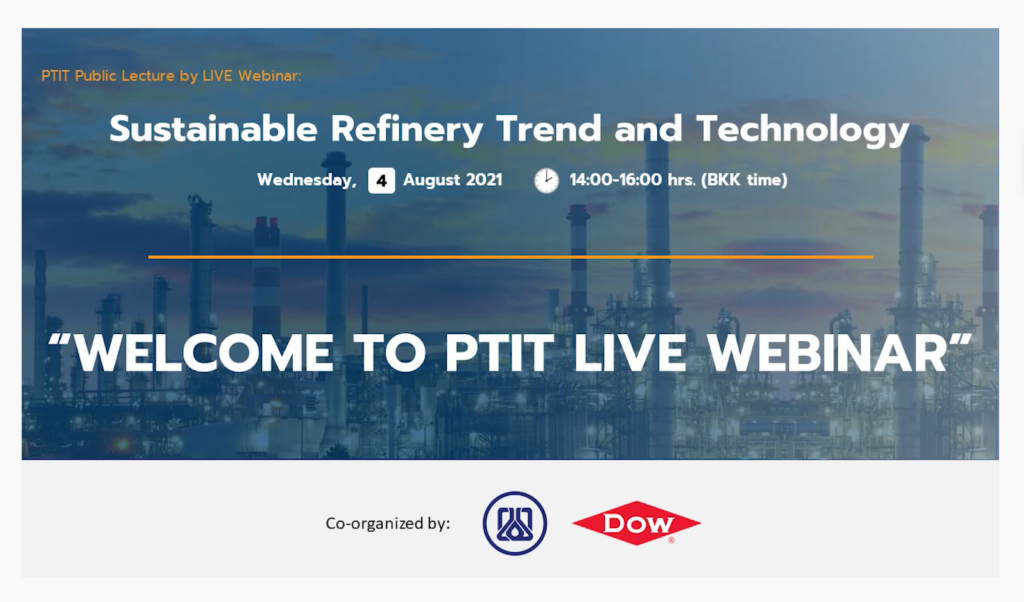

Vichan has also pointed out to six current trends in the refinery industry those are: 1. Improving asset utilization rate to resolve bottle neck in the operations; 2. The number of quality crude oil sources has declined. Therefore, refinery plants turn to use crude oil from sources that have more sulfur content. 3. More stringent sulfur specification in refinery products such as the marine fuels required by the International Maritime Organization (IMO). 4. Tightened sulfur dioxide emission standard 5. Having sustainability target that involves lower emission of sulfur dioxide and carbon dioxide. 6. Reduction of energy consumption.

–

“What refineries are looking for now is the proven, reliable and affordable technology that will help to improve operation efficiency through reducing energy consumption as much as possible, minimizing unplanned shutdown or turnaround, lessening corrosion, providing longer equipment operational lifecycle, extending catalyst life and environmental protection will absolutely be improved consistently. Meanwhile, these all advantages have to come with no large additional capital investment needed.”

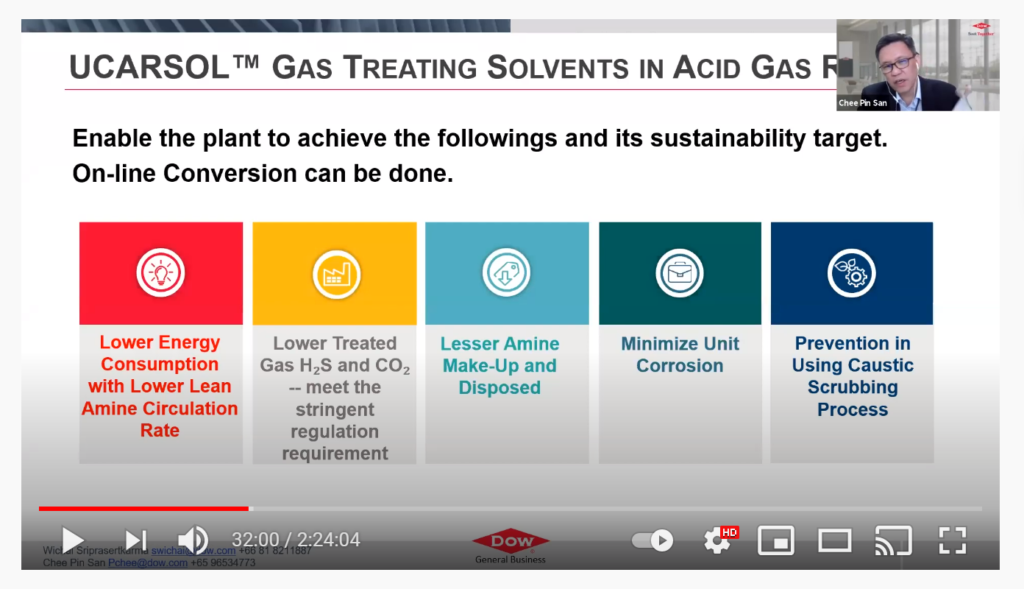

To cope with those refinery’s expectations, Dow has developed the UCARSOL as the latest innovative gas treating solution to capture GHG emitted by sizable industrial factories such as oil refinery, gas separation plant, electricity generating plant and fertilizer production factory, to achieve both improved efficiency and environmental protection.

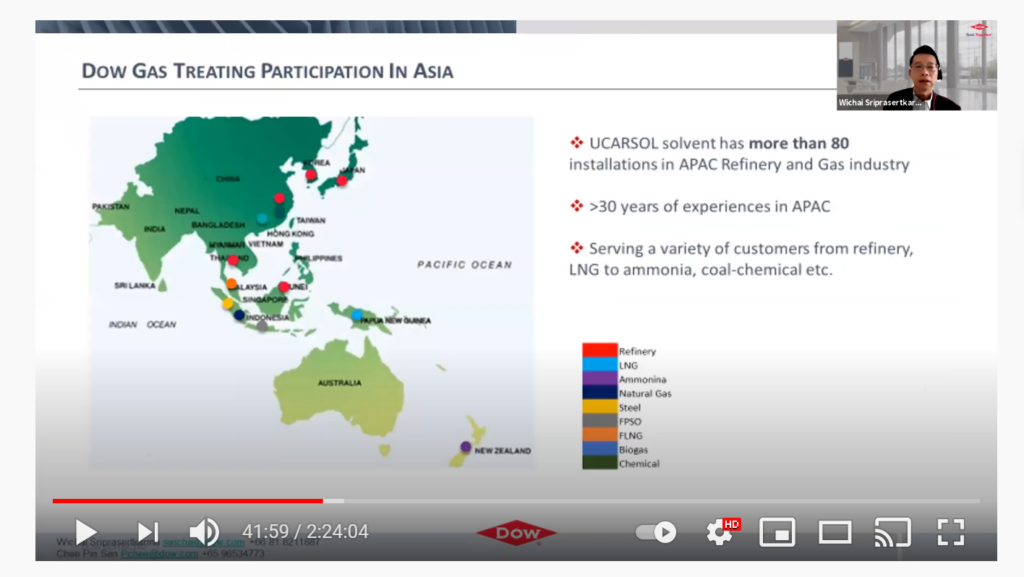

Chee Pin San, APAC Technical Leader, Energy Segment, Dow Industrial Solution, and Wichai Sriprasertkarnka, Account Manager, Dow Industrial Solution, told the audiences at the seminar that around 1,500 organizations in the world apply UCARSOL solvent at their operations, around 380 of which are refineries. In Asia, UCARSOL solvent has more than 80 installations at oil refinery and gas separation facilities.

–

UCASOL solvent can help reduce gas emission to the environment while assist in reducing corrosion and minimize energy consumption. Dow also provides Amine Management Program that is a comprehensive service program designed for refineries and users. Users of UCASOL solution include refinery in South Korea and power plant in Japan have successfully retrieve their energy consumption and GHG emission goals.

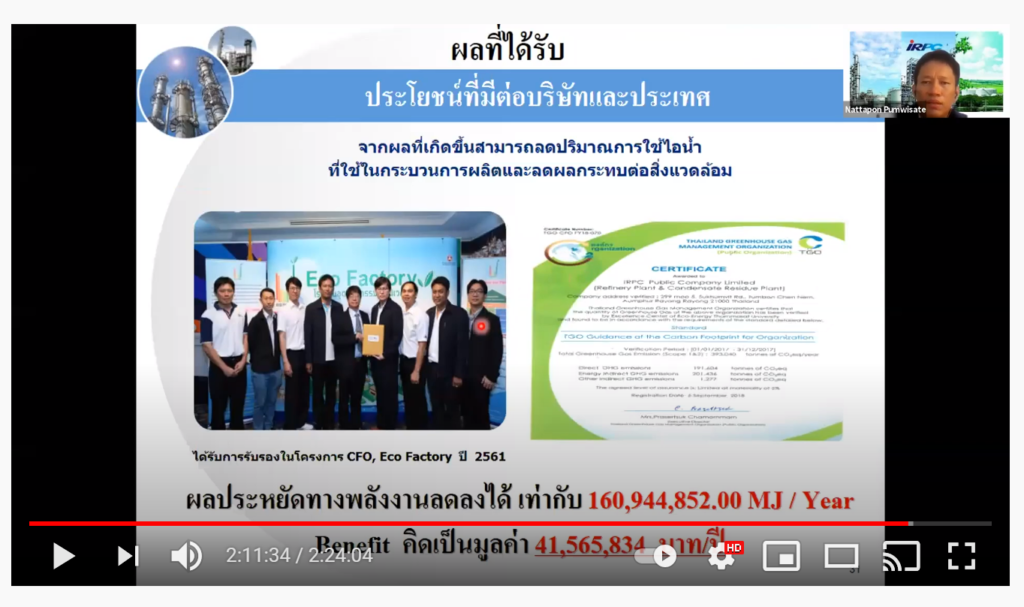

Nattapon Pumwisate, Senior Engineer, IRPC Plc, said IRPC has successfully adopted UCARSOL technology at its operations and lower steam consumption with result to saving value at THB41.5 million per year. The company can also minimize gas emission to the environment. He added that IRPC is the 1st in Asia and 4th in the world succeed in UCARSOL installation project.

Following such the success of energy saving and enhanced environmental protection, IRPC won Thailand Energy Awards 2020 and also represented Thailand in the Asian Energy Awards 2021 contest.

–